Smart automation and robotization for the industry of the future

Consulting

Driven by innovation and technical excellence, we deliver custom-engineered solutions. We optimize CNC and forging machines, as well as measurement fixtures. We implement traditional and collaborative robots into production processes – from clear vision and simulation to full implementation.

Programming

We deliver advanced programming for industrial robots and Siemens PLC systems. Our solutions are customized to your processes, ensuring uncompromising reliability, high repeatability, and long-term operational stability.

Development

Our strength is in integrating technology, automation, and smart factories. We create holistic solutions that unite mechanical, electrical, and software engineering – enabling greater efficiency, reduced errors, long-term competitiveness, and sustainable growth.

Service & Support

Fast and reliable service support. Backed by a highly skilled technical team, advanced diagnostics, and access to original spare parts, we reduce downtime and ensure safe, stable, and long-term reliable equipment performance.

Why choose MTEH?

TECHNOLOGY that follows your production goals

We help companies optimize their production processes with efficient and reliable automated robotic solutions. Our team combines technical knowledge, experience, and advanced software tools to develop solutions tailored to your specific requirements.

We start each project by understanding your goals, based on which we design comprehensive solutions – from concept to implementation. We incorporate our own development products into these solutions whenever this enables greater efficiency or a competitive advantage.

Our approach is based on cooperation and flexibility. We always seek the best solutions for your challenges.

+

Years

experience

+

Robotic cells

+

Dedicated machines

%

Satisfaction

Industry 4.0: Your next step towards smart manufacturing

Investing in the automation and robotization of manufacturing processes is a strategic decision that brings measurable benefits.

Together with our clients, we have successfully completed numerous projects. Delivering an excellent experience starts with a deep understanding of the needs and expectations of our business partners and customers. Consistency and integrity in the execution of Industry 4.0 projects are key to achieving mutual satisfaction.

Reduced errors and less waste directly impact the cost-effectiveness of production.

Stable quality and repeatability of production

A high degree of precision and traceability ensures compliance with requirements even in industries with the most stringent standards, such as the automotive, medical, and food industries.

Reduced changeover times between series and continuous operation increase throughput and enable a faster response to changes in production.

Increased production capacity and flexibility

The modular approach allows for quick adaptation to new changes in production and optimization of lines without major interruptions.

Comprehensive control and continuous process optimization

Advanced control systems enable real-time changes to key indicators (OEE, consumption, waste), rapid detection of deviations, and data-driven process optimization.

End-to-end solutions

Are you looking for a reliable path to more efficient production?

Promotional video of production robotization at Impol d.d., Slovenska Bistrica.

Part of Marovt Group

MTEH is an important member of the Marovt Group, which brings together companies that originated from the parent company Marovt d.o.o. In addition to Modern Technologies, the group includes five other companies operating in various fields. The group is built on a long-standing tradition and is committed to continuous development, innovation, and the delivery of high-quality services and products.

Products

Mbase & MTray

Innovative technology for optimizing CNC machine processing and efficient component palletization.

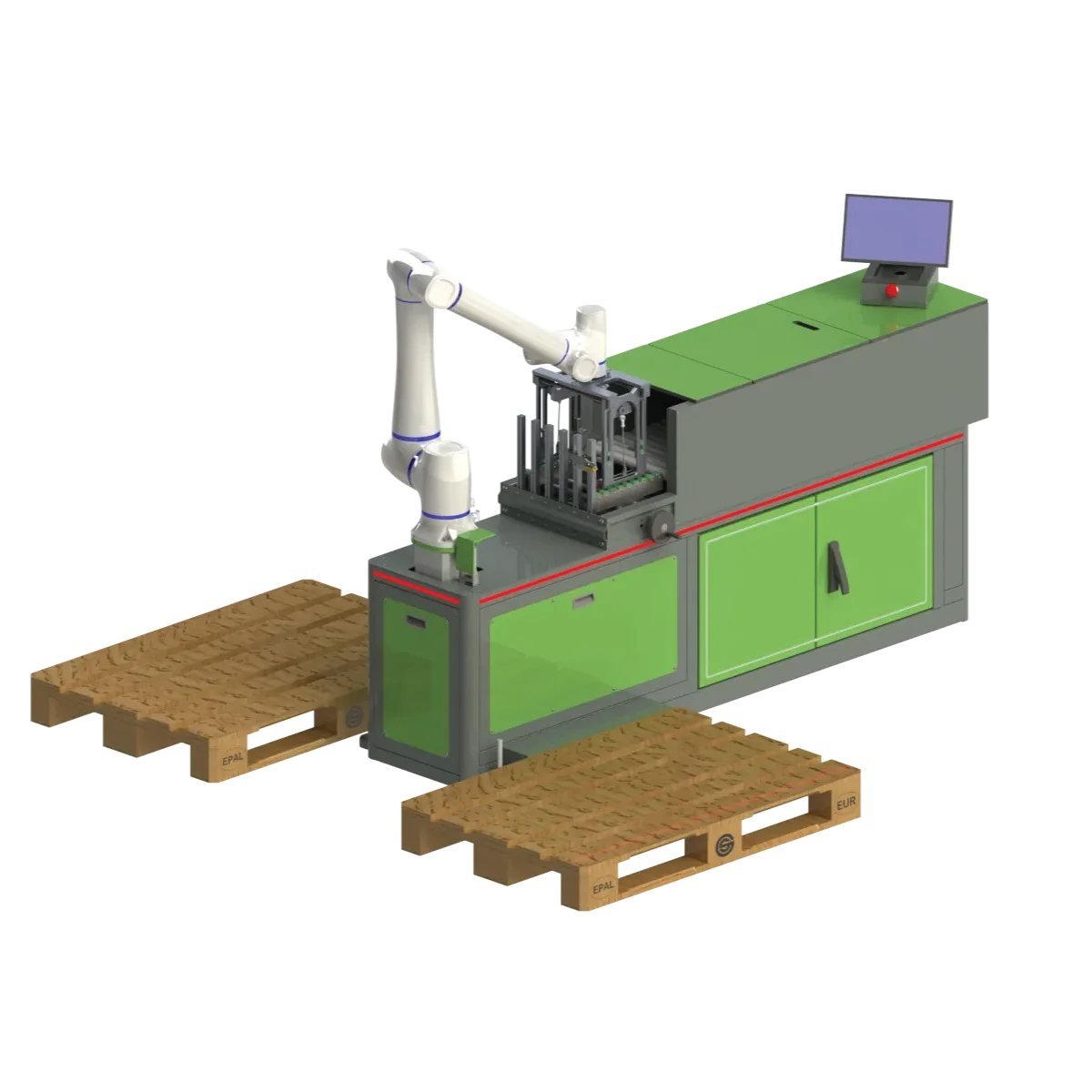

PalletFlock

PalletFlock is an indispensable component in modern, technologically advanced automated production processes.

Automatic Piece Stocker

Introducing an innovative stocker with 7 drawers, which significantly increases the autonomy and efficiency of the process.

BinPicking

BinPicking is a universal system that uses artificial intelligence for independent learning and picking of arbitrary shapes.

Are you looking for a reliable path to more efficient production?

Our team develops advanced solutions for the automation and robotization of production processes. We upgrade existing machines, adapt systems, and develop new solutions tailored to your needs. We specialize in systems for servicing CNC machines and other processing equipment, programming PLC controllers and industrial robots, and optimizing production according to lean manufacturing principles.